CVT Guarding

Olin Baja SAE

Skills Advanced: CAD (SolidWorks, Onshape), Sheet Metal Modeling, FEA/Topology/Frequency Studies, Statics, Sheet Metal Fabrication, Lathe, CNC/Manual Mill, Waterjet, Agile, Project Management

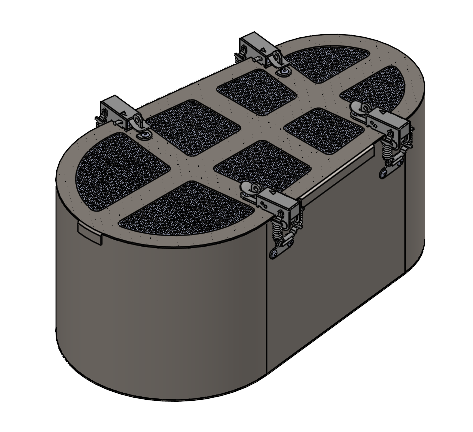

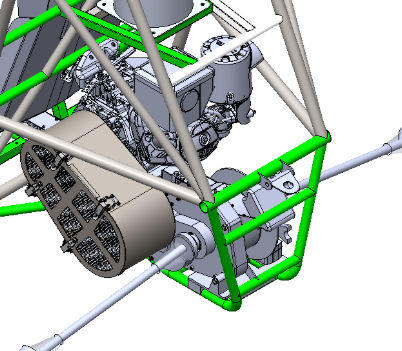

Objective: Protect the Continuously Variable Transmission (CVT) on the Olin Baja buggy with a rules-legal cover. Prioritize manufacturability and CVT accessibility/maintenance.

Previous CVT guarding designs on Olin Baja vehicles were extremely restrictive to CVT maintenance. They were unable to be completely removed from the car, and removing the front cover plate was a tedious process that did not allow the CVT to be removed or maintained reliably. In this design, I prioritized full accessibility and removal of the CVT and guarding in as little time as possible, optimizing the powertrain for the fast-paced competition environment.

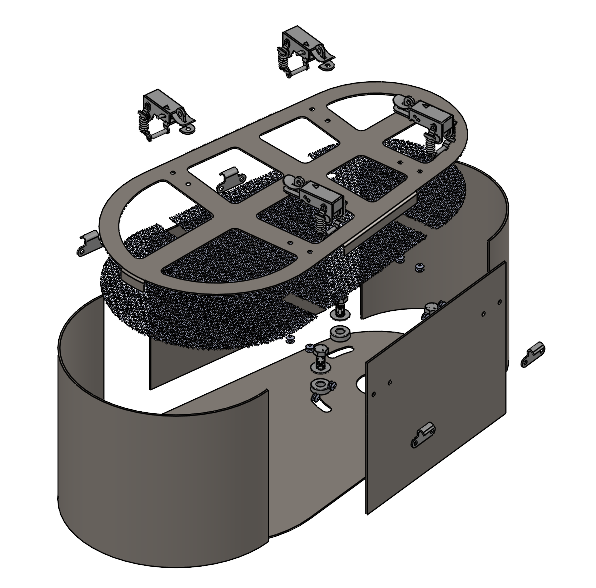

Design:

14 ga. Hot-Rolled Mild Steel Sheet

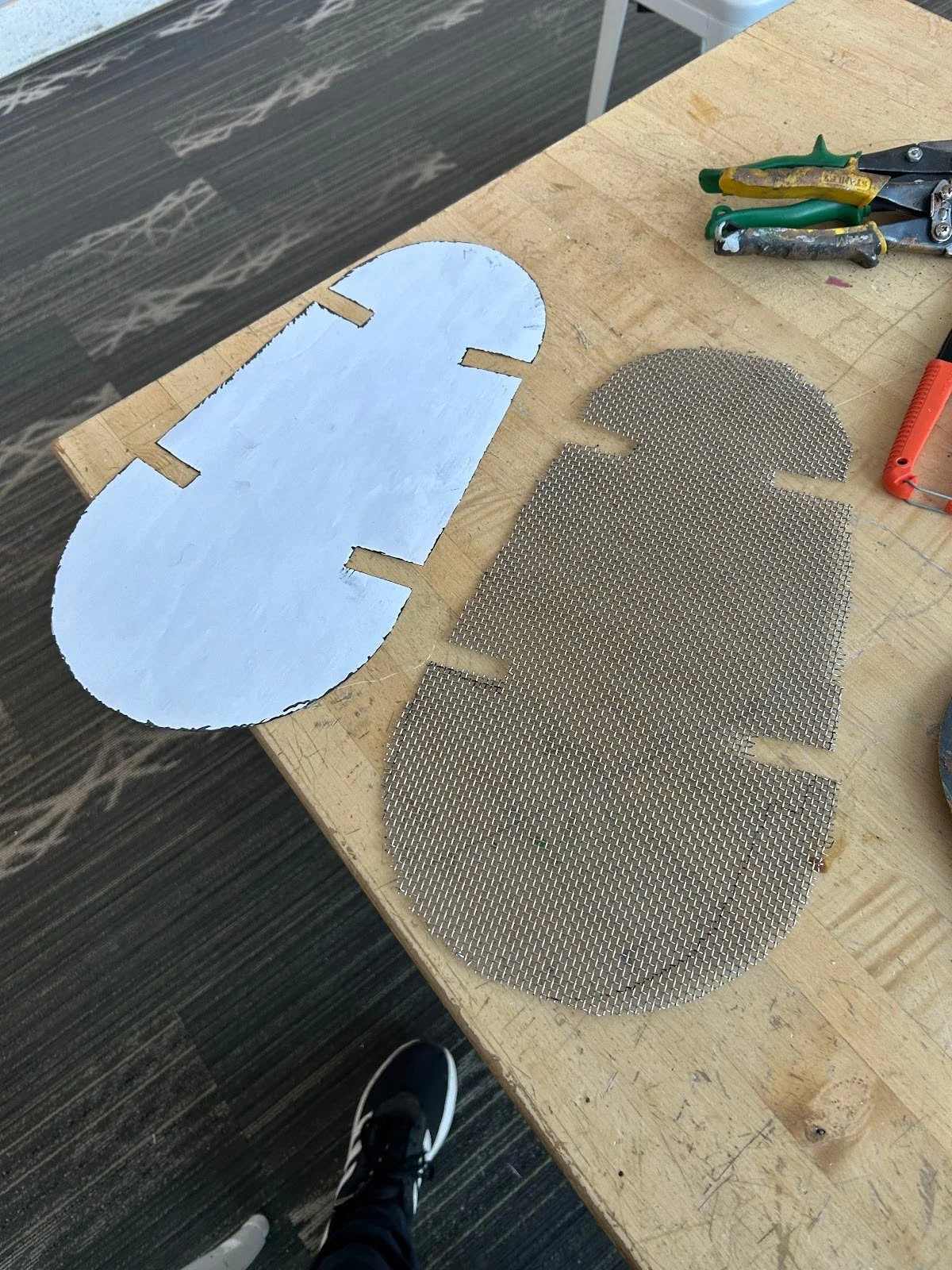

Steel mesh allows airflow while preventing contamination and bodily harm

CAD done using SolidWorks sheet metal

Adjustable mounting pattern for assembly adjustments on the fly

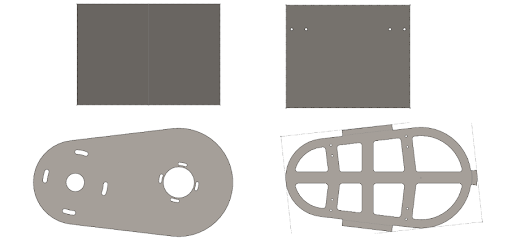

Fabrication:

Waterjet front and rear mounting plates

Plasma cut & bend side panels with roller/finger brake

TIG weld permanent guarding together

Spot weld front Mesh

Paint guarding & rivet on the latches

Done!

The new design is comprised of a permanently mounted rear plate and protective hoop with a removable front cover. The permanent guarding bolts to the engine’s PTO shaft face and gearbox casing, ensuring rigid and vibration-resistant mounting. The front plate is attached with 4 sprung, locking latches, enabling full CVT access within 10 seconds, in contrast to the previously inaccessible guarding.

I continue to support this team as one of two Drivetrain Leads. We use the Agile framework for task management, identifying blockers to our progress and determining how to resolve them. I look forward to continuing to build my design, manufacturing, and management skills and expertise with this team!