Nordic skate pinning process enhancement

Arctic manufacturing services llc

Skills Advanced: Wood Fabrication, CAD (Fusion360)

Objective: Samson Shepherd creates Nordic Skates in his company, Arctic Manufacturing Services LLC. His current manufacturing process includes a step in which spring pins are inserted into holes in the aluminum extrusion and blade. This step currently has two issues. One, the skate is unsupported on the edges and is often hard to position. Samson uses a 1-2-3 block to keep the skate in place. Two, the holes in the skate can be difficult to maneuver into place by hand beneath the machine. This makes pinning the skates a tedious process that could be made much easier for comfort when pinning.

To help Samson with the skate pinning issue, I prioritized ease and hand-comfort in the process. Using a 1-2-3 block to hold the skate on the press meant that only a small portion of the skate was supported, requiring lots of finger strength to stabilize the skate on the block while using the other hand to operate the press. The skate then had to be removed and set down on the table to insert the next pin into the press, and repositioned once the pin was ready.

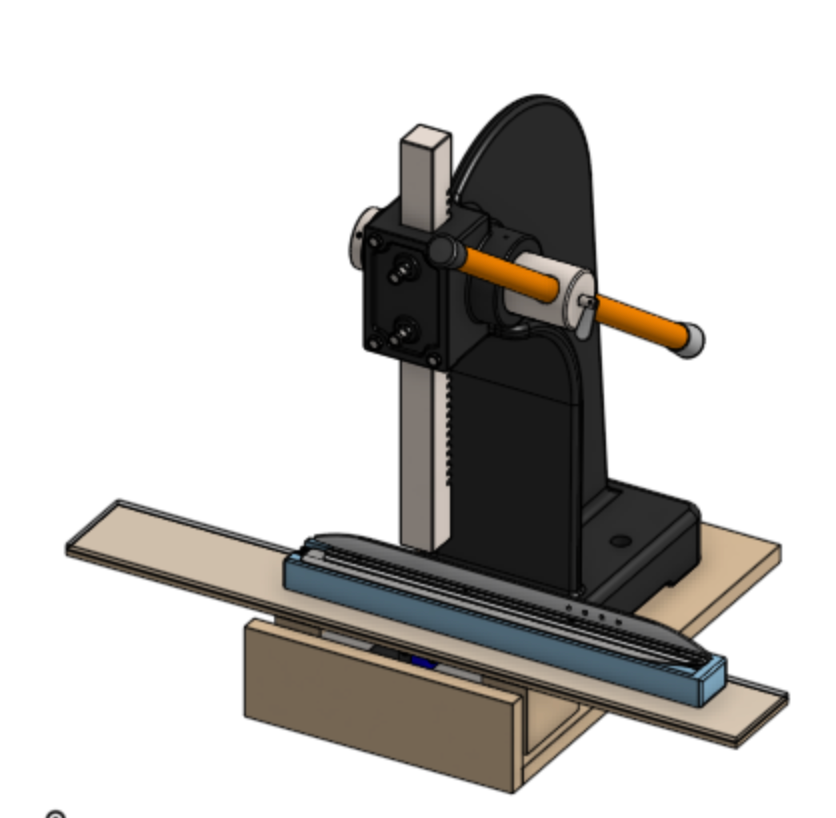

After this research, I solved the first problem of having to remove the skate from the press between each pin by creating a wooden plate that the press set into, creating a large operating workspace that fully supported the length of the skate and located the pinning tool above the operating area.

This fixture allowed for much more comfort during the pinning process. It was no longer required to strain to hold the skate to the block while pinning, and the skate could be left in place while putting in a new pin to the tool. New sleds could be created as needed for varying skate designs, and the overall system remained extremely cost-effective at under $50.

The project began by researching existing options for such a pinning process to see if any off-the-shelf tools might fit Samson’s use case. Unfortunately, all of the cost-benefit analyses came back negative for these systems, as many of the existing systems didn’t fit the one-man operation style of Samson’s shop.

Once the whole skate could be supported, I focused on the positioning of the skate underneath the pinning tool. The front of the arbor press has a convenient opening, allowing me to create and mount a small 3D-printed magnet holder that mounts to the wooden base, located exactly below the pinning tool. In addition, I added a layer of smooth polycarbonate to the working table of the base, and created a variety of 3D printed sleds that had a slightly offset negative profile of the skate, allowing each skate to rest in a sled in the pinning configuration. By placing magnets in the bottom of the sled that aligned with the pinning holes of the skate, the sleds could automatically roughly position the skate pinning holes below the pinning tool while still allowing for minor hand adjustments for alignment.