Beddy Clear

senior design project

Skills Advanced: C++, Arduino, Raspberry Pi, CAD (Onshape), Octoprint, FDM 3D Printing, Laser Cutting, Twingate

Objective: Design and fabricate a 3D-printer attachment that autonomously removes both failed and completed prints to improve printer efficiency at a reasonable cost.

Failed 3D prints are a major source of wasted time and material, especially when prints are run unattended. Hobbyist open-bed printers have no reliable way to detect failures, clear the bed, and restart printing remotely.

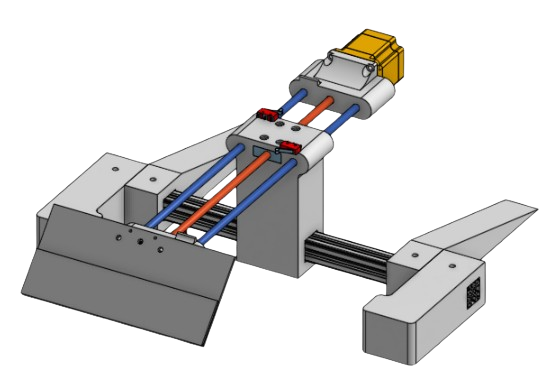

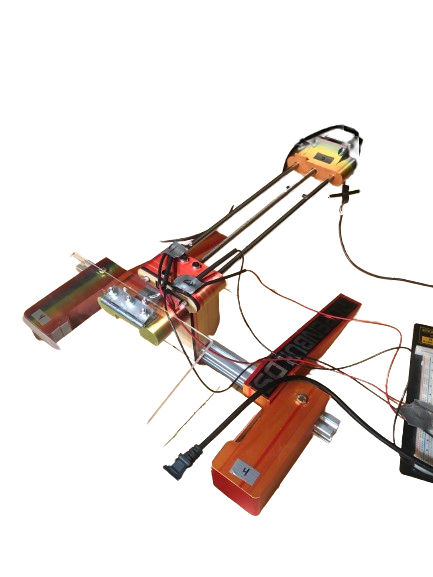

I developed the mechanical CAD model, fabricated custom 3D-printed and laser-cut parts, and integrated the system with printer electronics and remote software. The prototype combined aluminum extrusion and motion hardware with a Raspberry Pi running OctoPrint, microcontrollers for actuation and limit switches, and remote access via OctoEverywhere and TwinGate. The system was designed to be safe, non-intrusive, and deployable from an entirely different network.

To address this, I helped design and build Beddy Clear, a mechanical add-on that automatically clears a print bed after a failure. We generated and compared multiple concepts using structured ideation and a decision matrix, ultimately selecting a jackscrew-driven scraper with a compliant blade for safety, simplicity, and compatibility across printers.

Testing showed reliable deployment and successful removal of small prints, validating the mechanical concept and remote control pipeline. Larger prints revealed an important limitation: force was being transmitted through the printer’s belt system rather than efficiently peeling prints from the bed. This insight shifted the project’s direction and highlighted that print removal is a force-application problem rather than a force-generation problem.